Description

Welding machine Multi Characteristics

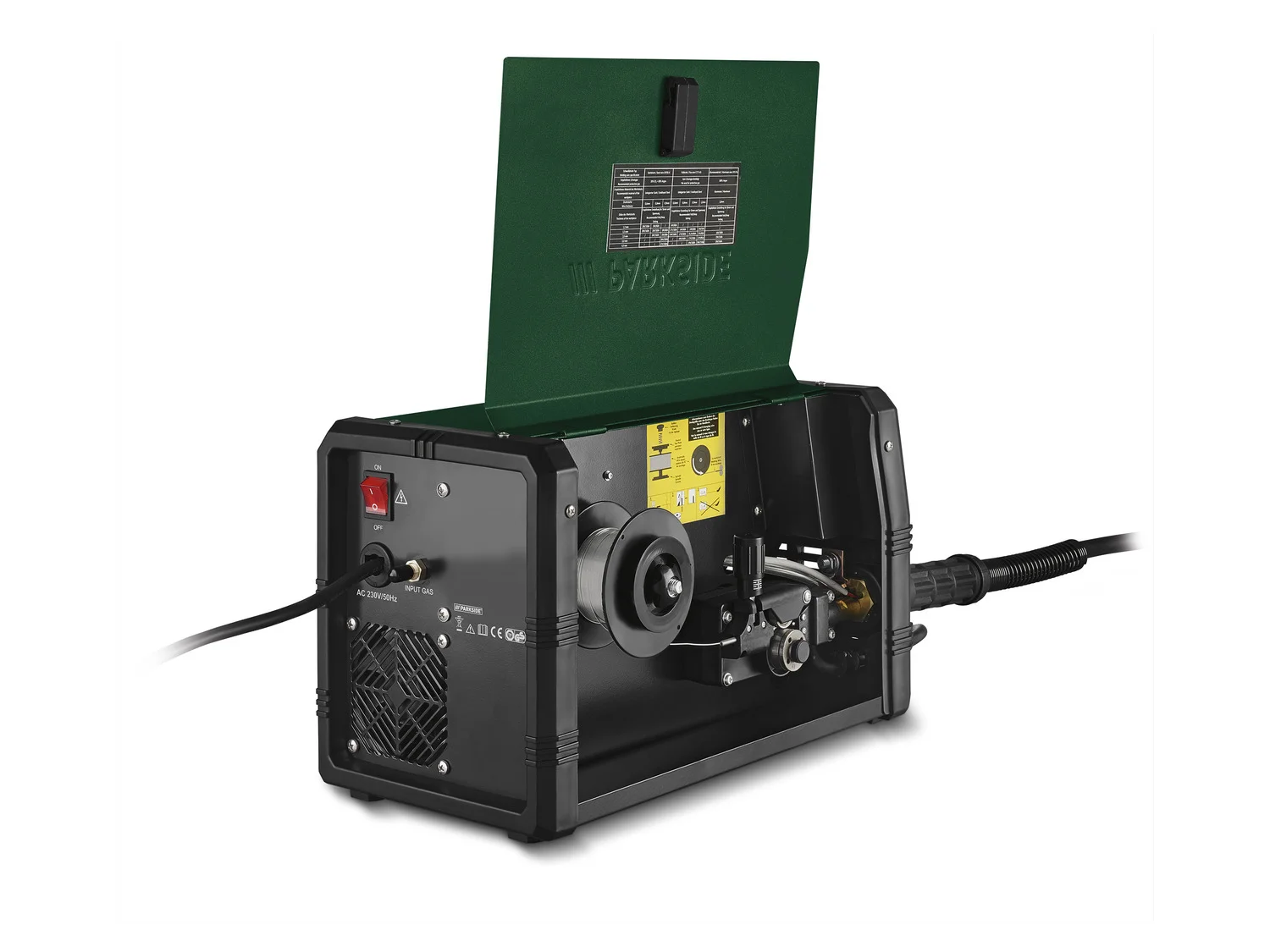

This powerful and compact welding machine is designed for versatility, allowing users to perform four different welding processes: MMA (manual metal arc, or stick electrodes), flux-cored wire welding, MIG (metal inert gas), and TIG (tungsten inert gas). With its robust metal housing and convenient carrying handle, it is built to withstand demanding work environments while being easy to transport.

- 4 welding processes: MMA (stick electrodes), flux cored wire, MIG (inert gas) and TIG (tungsten inert gas) I

- For welding stainless steel, steel, iron and aluminium

- Powerful compact device with robust metal housing and carrying handle

- Integrated, automatic filler wire feed in the side hinged lid compartment

- Ergonomic MIG flux-cored wire torch with soft grip and 2 m supply cable

- MMA electrode holder and 2 m cable including ground cable

- Easy setting of welding parameters with 1 button and 2 dials

- Selection of welding process and type of cored wire

- Digital displays for welding current (A) and voltage (V)

Design and Construction

- Compact and lightweight: The main unit weighs approximately 7.7 kg, making it portable and user-friendly.

- Robust metal housing: Offers durability and protection against environmental damage.

- Ergonomic design: Features a soft-grip MIG flux-cored wire torch with a 2 m supply cable for comfortable handling.

- Side-hinged wire compartment: Facilitates quick loading and unloading of welding wire spools.

- Integrated cooling system: Enhances the longevity of the machine by preventing overheating during extended use.

Included accessories:

This welding machine comes equipped with a comprehensive set of accessories, ensuring that users can start welding immediately upon setup:

- MMA electrode holder with 2 m cable

- 5 welding electrodes:

- 2 x 1.6 mm

- 2 x 2.0 mm

- 1 x 2.5 mm

- MIG welding torch with 2 m cable

- 200 g steel-cored wire

- 200 g aluminium solid wire

- 5 nozzles:

- For steel-cored wire: 0.6 mm, 0.8 mm, 0.9 mm, 1.0 mm

- For aluminium wire: 1.0 mm (pre-assembled)

- Welding shield: Lightweight and protective.

- High-quality slag hammer with combination wire brush: Essential for post-weld cleaning and slag removal.

- Ground cable with ground clamp: Ensures a safe and effective welding connection.

Technical data

- Input power: 4300 watts (operating at 230V).

- Open circuit voltage:

- TIG: 52 V

- MMA/MIG: 56 V

- Welding current range:

- MIG: 50 A/16.5 V – 160 A/22.0 V

- MMA: 30 A/19.2 V – 140 A/23.6 V

- TIG: 30 A/11.2 V – 200 A/18 V

- Welding wire compatibility:

- Maximum drum capacity: 5000 g

- Wire diameter: Up to 1.0 mm

- Power cable length: 2 meters, ensuring flexibility in the workspace.

Material

sheet steel, plastic

Mass

ca. 44,2 x 21 x 28,3 cm

Safety Features and Considerations

- Class A welding equipment: Designed for industrial or professional use rather than domestic applications due to potential electromagnetic interference.

- Electromagnetic compatibility: This machine is not intended for areas where the power supply is via a public low-voltage system, as ensuring electromagnetic compatibility in such locations may be difficult.

- Built-in thermal protection: Automatically shuts down the welder to prevent overheating and damage.

- Stable arc control: Ensures precise and consistent welding quality.

Weight

- Main unit: approx. 7.7 kg

- Welding shield: approx. 174 g

- Slag hammer with wire brush: approx. 89 g

- Ground cable with ground clamp: approx. 610 g

- MIG torch with welding cable: approx. 1,490 g

- MMA-Electrodenhalter: approx. 700 g

notes

This Class A welding equipment is not intended for use in domestic establishments where the power supply is via a public low-voltage supply system. It may be difficult to ensure electromagnetic compatibility in such areas due to both conducted and radiated disturbances.

I TIG torch and TIG electrodes not included.

- User-friendly controls: Ideal for both beginners and experienced welders looking for a multi-functional welding solution.

- Versatile applications: Suitable for workshops, repair shops, automotive work, construction, and metal fabrication.

- Optimized for various welding positions: Supports flat, horizontal, vertical, and overhead welding operations.